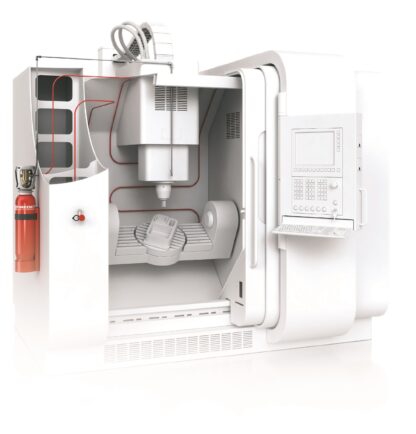

COMPLETE SYSTEMS FOR CNC MACHINES

Code.:

ERP:6c43c67f3413

Product Information

A complete Detection & Suppression pre-engineered system for CNC Machines

• CO2 or FM-200 Extinguishing Agent

• Easy / Flexible Installation

• Quick & Effective Suppression

• No electricity or moving parts

• Highly economical

Reduces even the most critical CNC machines fire risks:

• Combustion of oil residues or machined metals due to coolant system malfunction, tool breakage or improper maintenance.

• Extensive machine repair

• Late orders due to downtime

• Extensive cleanup if sprinkler system actuates

THE FIREDETEC® DIFERENCE

FireDETEC® systems use a proprietary continuous linear sensor tube that reliably detects and actuates release of the extinguishing agent using pneumatic technology. It is more flexible, space efficient and cost eff ective Detection Method.

1. Quick & easy Installation directly inside CNC Machines:

The flexible sensor tubing is easily installed directly on the walls and roof of the machine enclosure.When in service, the tubing is pressurized with Nitrogen at 16 bar.The dynamics of pressurization make the tubing more reactive to heat.

2. Early Fire Detection:

If a flame-up occurs, the heat of the fire causes the pressurized sensor tube to burst at the hottest spot (approx. 110°C).

3. Instant Suppression:

The sudden tube depressurization actuates the special pressure differential valve and instantly floods the entire machine area with CO2 or FM-200 extinguishing agent. The fire is quickly suppressed just moments after it began minimizing damage and downtime.